High Thermal Shock Resistance And Zero Expansion Silica Bricks/ Fused Silica Bricks For Glass Kiln

- Apparent porosity:≤ 22

- Flux index:≤ 0.4

- Cold crushing strength :≥ 30

- True density :≤ 2.34

Description

Description

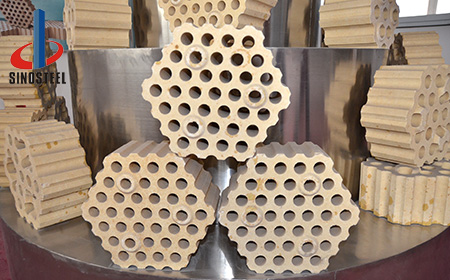

Zero expansion silica bricks is high thermal shock resistance and zero expansion silica bricks produced with fused silica as the main raw material , with resistance to thermal shock when warming up , high strength, low expansion rate, acid erosion resistance and many other advantages, it is the best choice for glass kiln as hot patching bricks.

High thermal shock resistance & zero expansion silica bricks has more advantages, like low expansion and high thermal shock resistance, designed for coke oven and glass kiln in hot maintenance. And it would be repair when the kiln is working, need not stop kiln’s working process. When masonry, we do not need to reserved expansion joint, it’s an ideal product for coke oven hot maintenance.

Zero expansion silica bricks is high thermal shock resistance and zero expansion silica bricks produced with fused silica as the main raw material , with resistance to thermal shock when warming up , high strength, low expansion rate, acid erosion resistance and many other advantages, it is the best choice for glass kiln as hot patching bricks.

High thermal shock resistance & zero expansion silica bricks has more advantages, like low expansion and high thermal shock resistance, designed for coke oven and glass kiln in hot maintenance. And it would be repair when the kiln is working, need not stop kiln’s working process. When masonry, we do not need to reserved expansion joint, it’s an ideal product for coke oven hot maintenance.

Specification

| High Thermal Shock Resistance And Zero Expansion Silica Bricks/ Fused Silica Bricks For Glass Kiln | FS99 | ||

| SiO2 | ≥ | 99 | |

| Fe2O3 | ≤ | 0.3 | |

| Flux index | ≤ | 0.4 | |

| 0.2MPa refractoriness under load ℃ | ≥ | 1650 | |

| Apparent porosity % | ≤ | 22 | |

| Cold crushing strength MPa | <20kg | ≥ | 35 |

| ≥20kg | ≥ | 30 | |

| True density g/cm3 | ≤ | 2.34 | |

| Thermal shock water-cooled at 1100℃ (times) | ≥30 | ||